— Blogs —

—Products—

Consumer hotline +8618073152920

Consumer hotline +8618073152920 WhatsApp:+8615367865107

Address:Room 102, District D, Houhu Industrial Park, Yuelu District, Changsha City, Hunan Province, China

Technical Support

Time:2022-08-13 16:19:53 Popularity:918

Common problems with the use of ph sensors

In practical use, pH in practical use, the following problems may exist in pH sensors: reduced sensitivity/slope, sluggish response, noise signals and chemical damage.

(1) Sensitivity/slope: There is a certain theoretical relationship between pH and the electrode potential of the probe (see the aforementioned Nernst equation).

New pH probes can approach their theoretical slope (i.e. 59mv electrode potential per pH unit at 25°C), but sensitivity decreases as the probe ages or destroys. Most pH meters or amplifiers can control and vary their sensitivity to convert the voltage signal into a pH reading (usually labelled slope or sensitivity), which can be calibrated by mv or temperature (as temperature is the only factor that theoretically affects slope). It is worth noting that this is different from 'buffer setting' or 'zero control'.

The system is calibrated to a certain pH (controlled by a buffer setting) and then checked with one or more buffers. Unlike the expected result, the pH meter reading will systematically deviate from the pH of the known buffer.

If the line obtained is steeper, the slope is set too low; if the line obtained is flatter, the slope is set too high.

(2) Cleaning: The pH probe needs to be cleaned when it exhibits delayed response or reduced sensitivity. pH probe deterioration is mainly due to contamination of the porous plug by substances in the fermentation broth, which will turn from white to brown or black if contaminated.

To prevent contamination, the pH probe can be immersed in a 10mmol/L HCl solution, which will not damage the pH sensor (this can also be used to routinely store the pH probe between runs). Sometimes the addition of pepsin helps to remove protein precipitation.

If HCl treatment does not work, the following two methods can be tried, although they carry some risk of damaging the pH probe. Immerse the pH probe in a solution of about 1% H2O2 for about 1 to 2h; or perform a gentle mechanical cleaning of the porous plug, i.e. use a sharp blade to scrape away the deposits on the outer surface.

(3) Electrical interference: The high impedance of the pH meter and the amplifier line can create problems which make the pH probe more sensitive to noise from induced voltages from stray field inlets from other electrical equipment and more sensitive to erroneous responses caused by trace amounts of current leakage between the two terminals containing the pH probe signal.

For this reason the manufacturer of the pH sensor or pH meter provides special shielded conductors and terminals. If excessive noise is present, the pH probe lead can be moved away from the other wires to reduce the noise. The stirrer motor may be a source of interference and this can be checked by turning the motor off for a few seconds.

Spikes on the pH trace correspond to the heater circuit being switched on or off (the switch can be observed by a light or judged by the sound of the relay switching in the heater control unit). Noise or inaccurate readings after autoclaving can reflect contamination of the terminals and wires caused by steam condensation during the sterilisation process.

(4) Protection against mechanical damage: pH probes are quite fragile and can be easily broken during installation and cleaning of the fermenter. It is therefore recommended that the pH probe is inserted later in the preparation of the fermenter (where calibration is required) and removed after use (dismantling the tank). Many cases of sensor breakage are due to lifting the top of the fermenter without removing the sensor.

To avoid breakage of the probe during storage between runs, a simple method is to place the sensor in a plastic measuring cylinder containing a special solution.

Choose a suitable size of cylinder so that the wider part of the probe can also be placed, with the spherical detection part suspended above the bottom (e.g. a cotton plug can be inserted into the bottom of the cylinder), and preferably with the cylinder secured by a clamp.

Prev:Calibration of pH Sensors

Next:How to troubleshoot the failure of the automatic weather observation station?

Related recommendations

Sensors & Weather Stations Catalog

Agriculture Sensors and Weather Stations Catalog-NiuBoL.pdf

Weather Stations Catalog-NiuBoL.pdf

Related products

Combined air temperature and relative humidity sensor

Combined air temperature and relative humidity sensor Soil Moisture Temperature sensor for irrigation

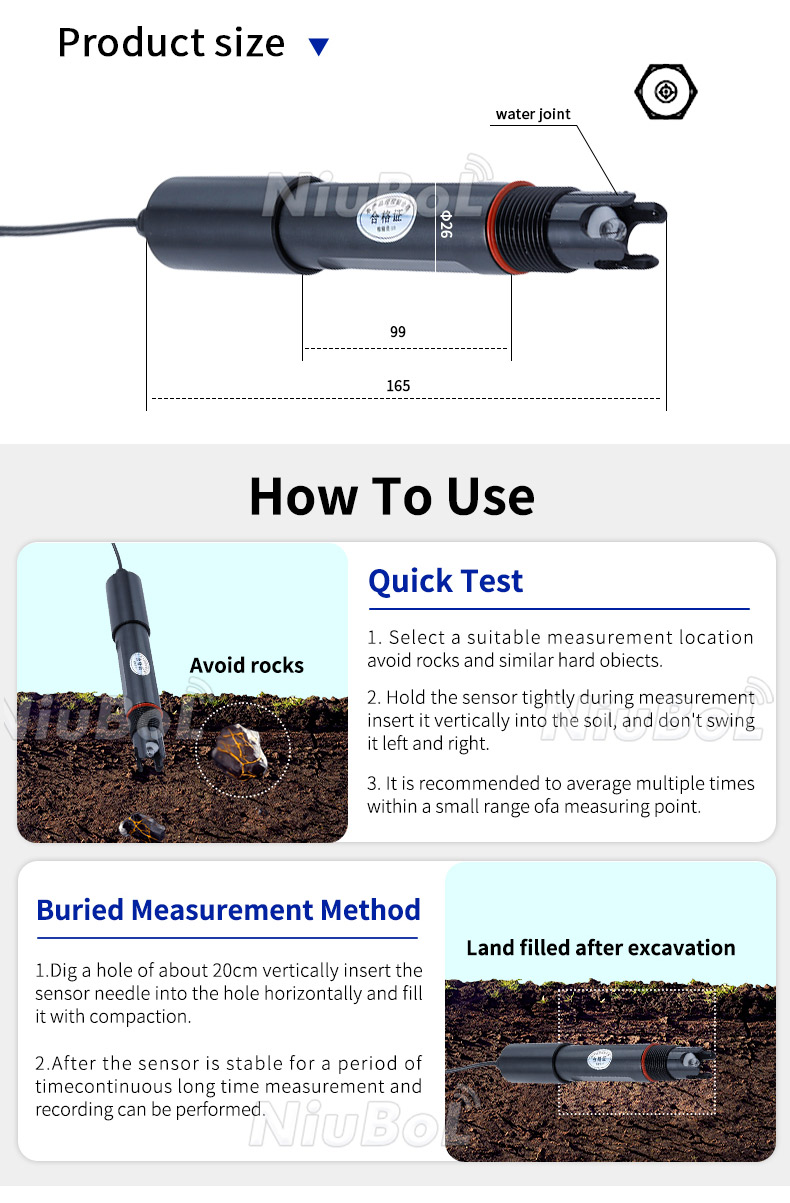

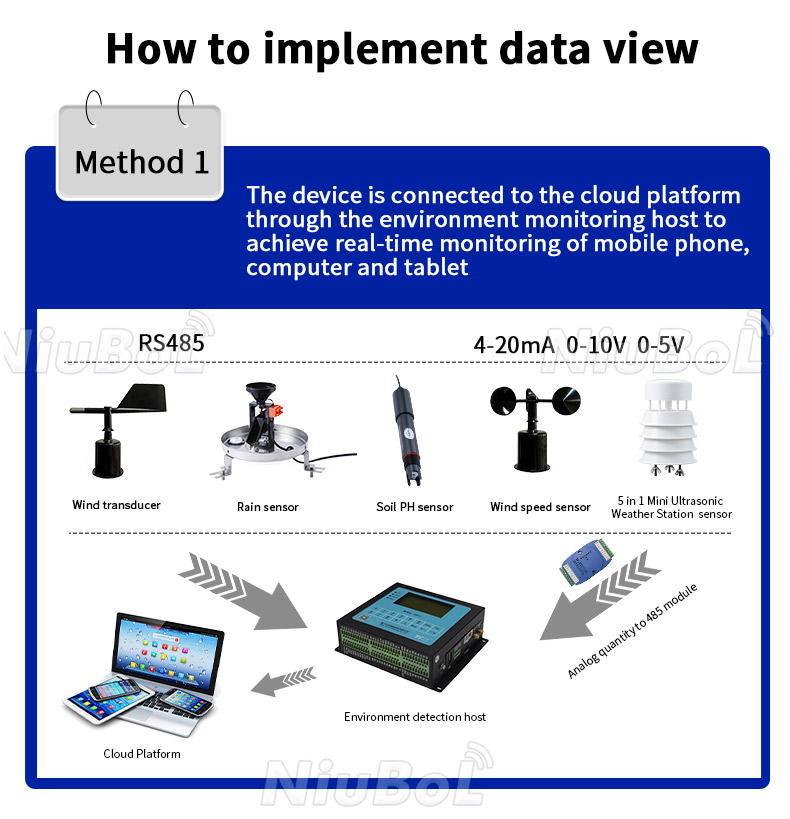

Soil Moisture Temperature sensor for irrigation Soil pH sensor RS485 soil Testing instrument soil ph meter for agriculture

Soil pH sensor RS485 soil Testing instrument soil ph meter for agriculture Wind Speed sensor Output Modbus/RS485/Analog/0-5V/4-20mA

Wind Speed sensor Output Modbus/RS485/Analog/0-5V/4-20mA Tipping bucket rain gauge for weather monitoring auto rainfall sensor RS485/Outdoor/stainless steel

Tipping bucket rain gauge for weather monitoring auto rainfall sensor RS485/Outdoor/stainless steel Pyranometer Solar Radiation Sensor 4-20mA/RS485

Pyranometer Solar Radiation Sensor 4-20mA/RS485

Screenshot, WhatsApp to identify the QR code

WhatsApp number:+8615367865107

(Click on WhatsApp to copy and add friends)